|

|

|

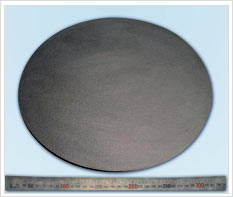

| JPX-300GⅢ (with optional unit) | φ 300 mm Al2O3 (RD: 98 %) |

|

|

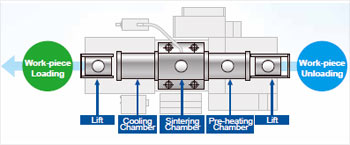

| “The World's Largest Tunnel-type Continuous SPS Production System” with Three-chambers and Automatic Materials Handling Conveyer |

|

| Model Name | JPX-120G | JPX-300G | JPX-600G |

| Maximum pressure | 1.2MN | 3MN | 6MN |

| Z-axis stroke | 150 mm to 600 mm(open height 600 mm to 1000 mm) | ||

| Stage size | φ 300 mm to φ 900 mm | ||

| Maximum temperature | 2,200℃(2,000℃ for normal use)* | ||

| Maximum pulse current output | 15000A / 20000A / 30000A / 40000A There are 4 types depend on different output. |

||

SPS system with Glove Box LABOX-125GH

Provided at reasonable price, SPS System with glove box(equipped with diffusion

pump) is the most suitable for research and development work for nano-phase

materials, thermoelectric conversion materials magnetic materials, etc.

This equipment can be operated from the charging of powdered materials

to the sintering without exposure into atmosphere (sample materials can

be transported from the glove box to the sintering chamber).